Our Product Categories

Dayton Lamina Expertise

Fast on-time, accurate delivery

Our Firm Delivery Schedule reduces your leadtime, maintenance downtime and inventory. Our in-stock catalog die components are available for immediate delivery.

Comprehensive product range

More variety than any other metal stamping tooling manufacturer, meeting all your metal forming tooling requirements.

World-wide distributor network

Dayton Lamina trained distributors are nearby to assist you in product selection, problem solving and order placing to assure you of receiving the highest quality.

Highest level of technical support

Most knowledgeable sales and technical support team in the industry, helping to solve your most demanding problems and maintain your productivity.

Metallurgical services

Expert investigations of metals and materials. We offer a confidential, rapid and reliable testing service, with expert support.

Global manufacturing facilities

The Dayton Lamina Team is dedicated to furnishing you with the highest quality, best value catalog and to- print special metal stamping tools and components.

Recent Articles

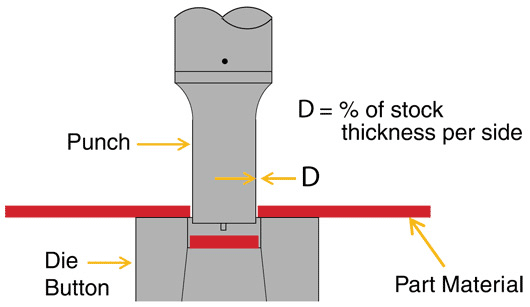

Aluminum Stamping Solutions

One of the most frequent problems encountered with perforating aluminum is punch galling. Aluminum, in general, possesses a gummy characteristic which causes it to adhere to a surface of the punch when it's drawn, pulled, trimmed, perforated, or pierced. This accumulation of material on the punch is known as galling (adhesive wear). The galling occurs both on the initial penetration into the material and extraction from the material.

Learn More