Build Your Part

- Price Not Available

- Price Not Available

-

-

0.000.00

Summary

Change configuration| {{summaryItem.Description}}: | None |

|---|---|

Product Applications

frequency and heavier-than-normal impact punching activity occurs and where optimum performance is required.

Dayton Jektole® Punches; Regular Punches; and Punch Blanks.

Unique Head Design

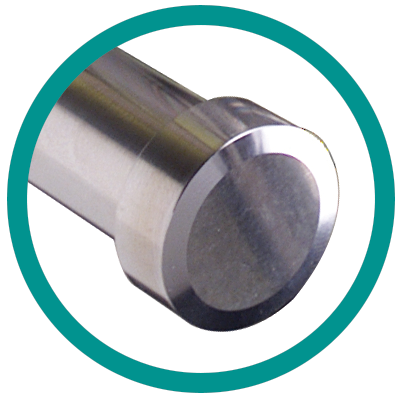

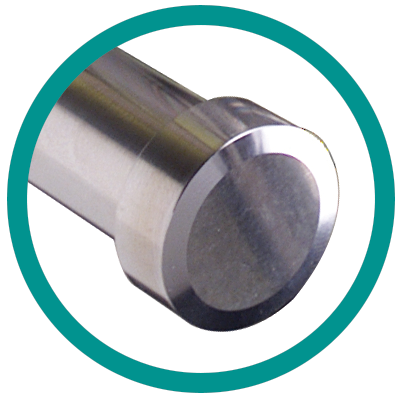

All Dayton TuffPunch® products are designed with a 10° angled head with a diameter equal

to the shank diameter (see photo). This design allows the perforating forces to travel

up from the shank and completely through the head. This eliminates the lateral shock

waves that would otherwise put stress on the outer edge of the head, resulting

in frequent failures—especially in heavy-duty applications.

All Dayton TuffPunch® products are designed with a 10° angled head with a diameter equal

to the shank diameter (see photo). This design allows the perforating forces to travel

up from the shank and completely through the head. This eliminates the lateral shock

waves that would otherwise put stress on the outer edge of the head, resulting

in frequent failures—especially in heavy-duty applications.

In addition, Dayton TuffPunch® products are available in common shear angle configurations to reduce punch load and minimize the risk of slug pulling. Shear angle configurations include: nail point; chamfer; conical; double shear; and single shear. For more information, see “Alterations” tab.

Cryogenic Treatment Standard

DayKool™ (XCR)—a cryogenic steel conditioning process used primarily with hard, thick materials to improve strength, toughness, and dimensional stability—is standard on all Dayton TuffPunch® products.

dispersed carbides provide more evenly distributed wear); less sharpening time; no loss of resistance after sharpening; longer die runs; and less downtime.

Special Features

Punches, retainers, and punch blanks are available in sizes other than those listed in the configurator. These special order products can be manufactured for a slight additional charge.

When configuring, you are asked to specify different designations for various non-standard dimensions. Once you have set the base information you can choose from the list of available alterations. Below is for reference.

Length Alterations

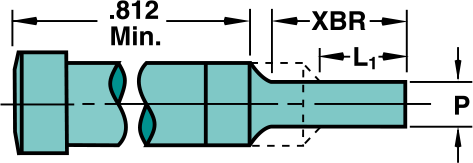

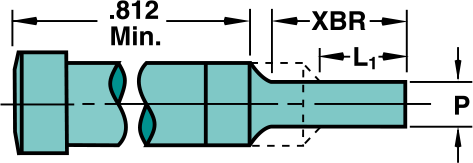

XBR (Straight Before Radius) It is recommended that point lengths be kept as short as possible for optimum strength

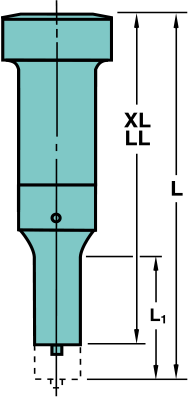

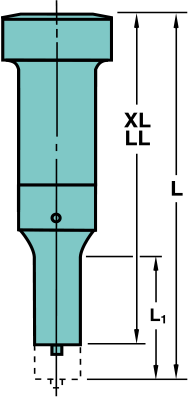

| XL | Overall Length Shortened (1.00 min.)

Stock removal from point end which shortens L1 length |

| XLB | Overall Length Shortened

Stock removal from point end. Point length L1 maintained (Min. shank length .75) | |

| LL | Precision Overall Length

Same as XL except overall length is held to ±.001 | |

| XK | No Side Hole For air ejection. No cost | |

| XS | Shear Angles See information below | |

| XJ | Smaller Jektole Components |

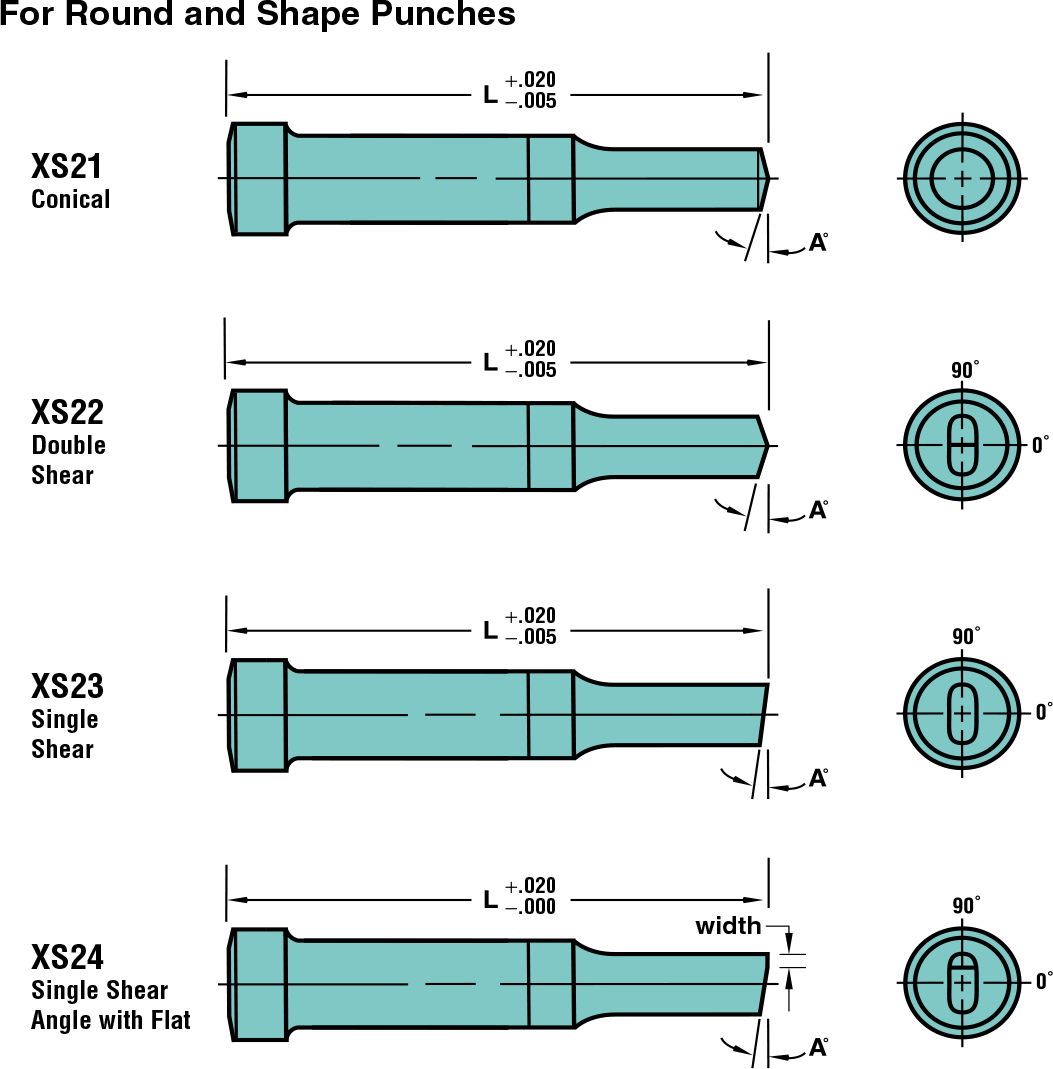

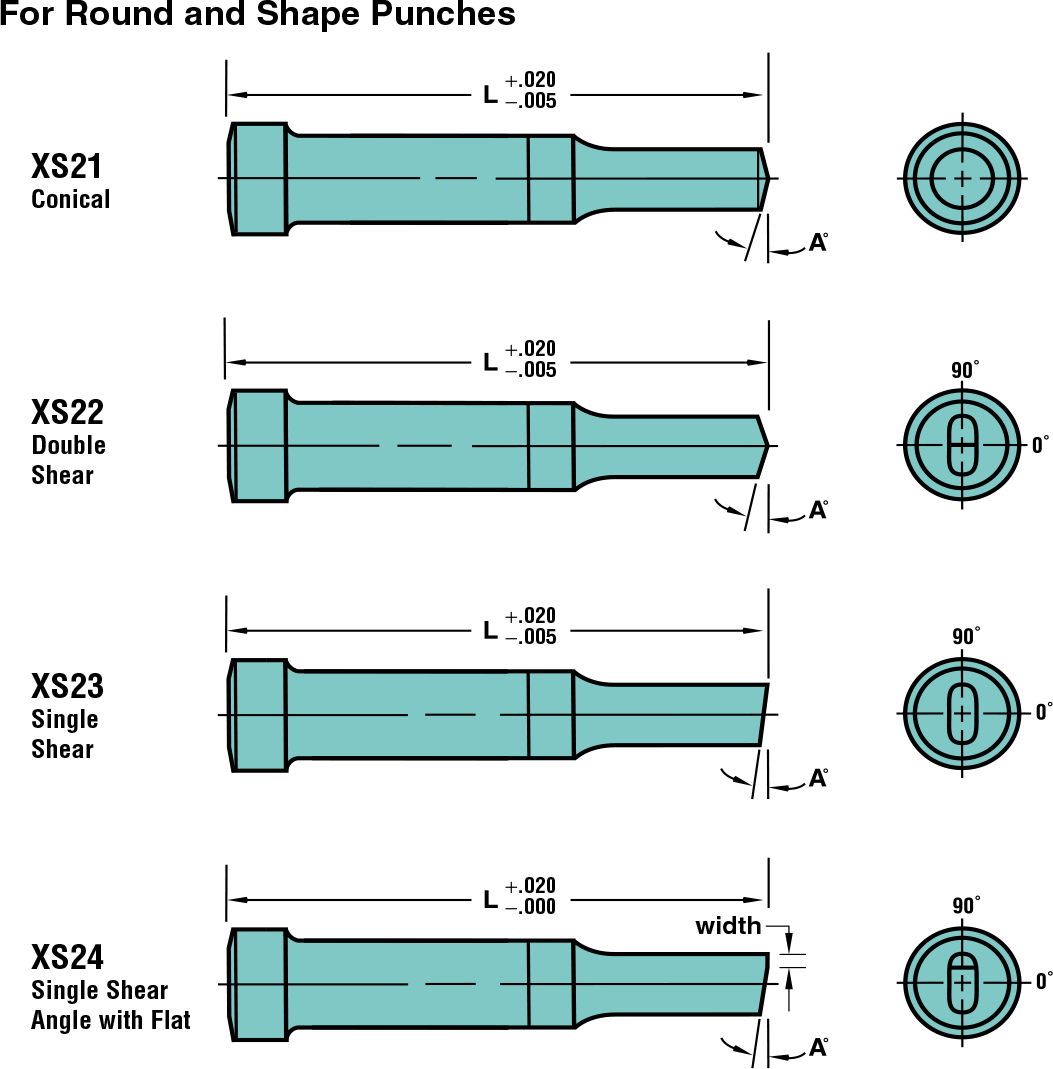

Shear Angles (XS)

TuffPunch® products are available in common shear angle configurations for all standard shapes.

Shear angles are available in any angle. Specify angle in whole degrees. if half degree is necessary, specify as a decimal, e.g., 8.5° (tolerance on all angles is +-15 minutes.) Use the chart below to determine the product designation, then simply add the alteration code shown next to the drawings, along with the angle desired.

LL not available on XS19, XS21, XS22 and XS23.

Our TuffPunch®

line of punches are available with the most common locking devices, flat, double flat and dowel. The standard location is at 0°, alternate locations of 90°, 180°, or 270° are available at no additional charge.

If you require a custom location we offer that as well use the Custom Locations codes below and specify your angle. All custom locations are measured counterclockwise from 0°.

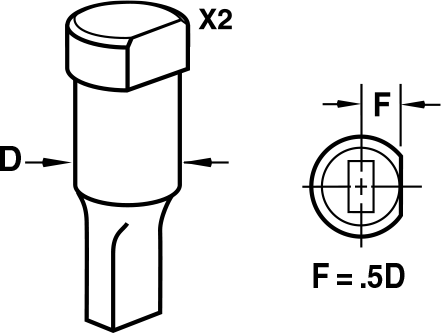

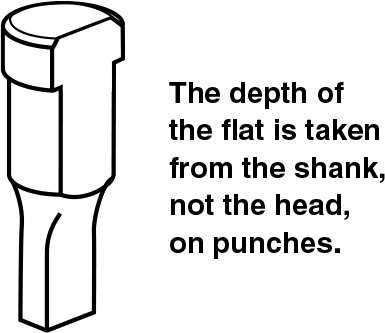

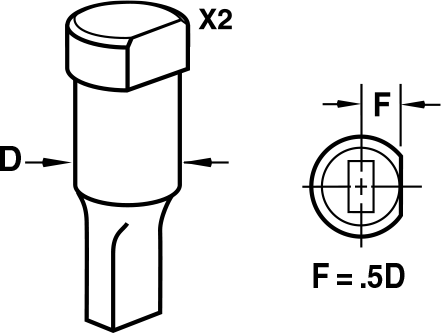

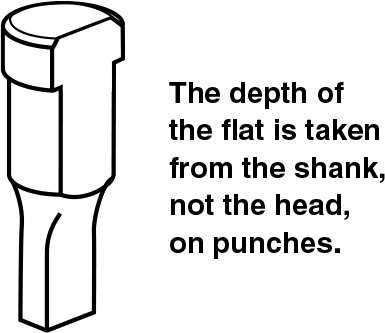

Single Flats

For Standard and Alternate Locations, specify X2

For Custom Locations, specify X5

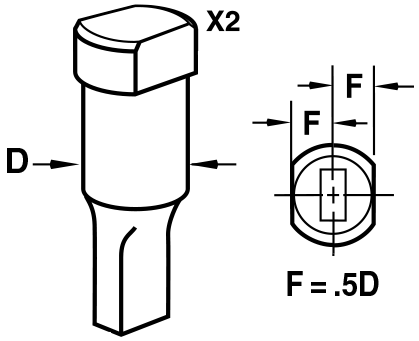

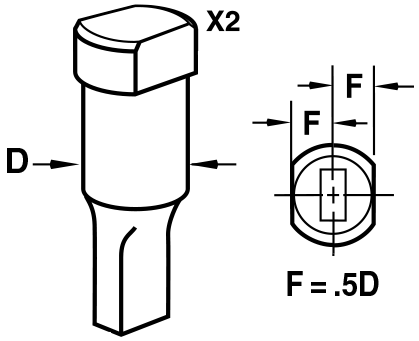

Double Flats

For Standard and Alternate Locations, specify X3

For Custom Locations, specify X6

Second Flat is Always Parallel to the first flat.

Additional Flats

Standard and Alternate Locations

| Code | Depth | Length |

| X81 | .060in (1.5mm) | .500in (13mm) |

| X82 | .060in (1.5mm) | .625in (16mm) |

| X83 | .060in (1.5mm) | .750in (20mm) |

| X84 | .060in (1.5mm) | Full Length |

| X85 | .093in (2.5mm) | .500in (13mm) |

| X86 | .093in (2.5mm) | .625in (16mm) |

| X87 | .093in (2.5mm) | .750in (20mm) |

| X88 | .093in (2.5mm) | Full Length |

| X89 | Specify Dimension | |

Custom Locations

| Code | Depth | Length |

| X91 | .060in (1.5mm) | .500in (13mm) |

| X92 | .060in (1.5mm) | .625in (16mm) |

| X93 | .060in (1.5mm) | .750in (20mm) |

| X94 | .060in (1.5mm) | Full Length |

| X95 | .093in (2.5mm) | .500in (13mm) |

| X96 | .093in (2.5mm) | .625in (16mm) |

| X97 | .093in (2.5mm) | .750in (20mm) |

| X98 | .093in (2.5mm) | Full Length |

| X99 | Specify Dimension | |

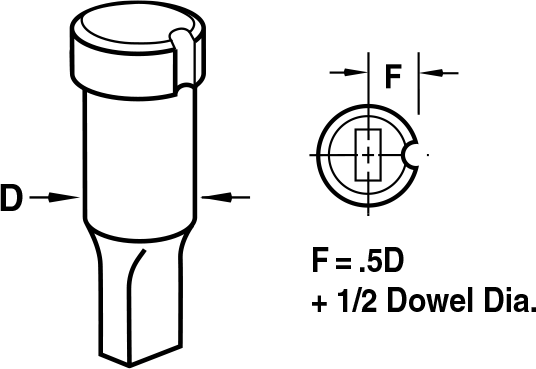

Dowel Slots

For standard and Alternate Locations,

specify X4 (.125 Dowel)

or X41 (.1875 Dowel)

For Custom Locations specify X7 (.125 Dowel) or X71 (.1875 Dowel)

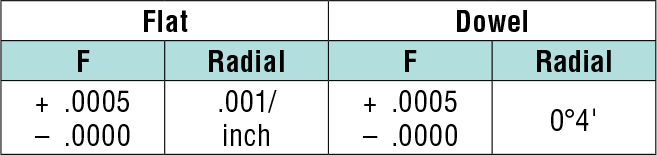

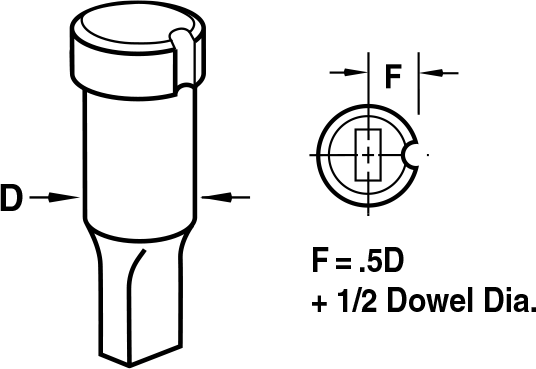

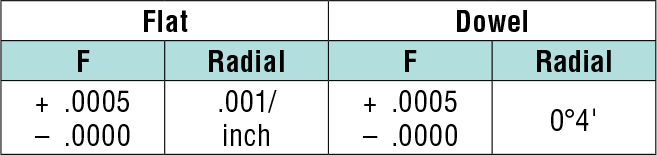

Location Tolerance

Coatings & Treatments

Punches can be coated to increase material hardness, reduce galling, and improve wear/ and or corrosion resistance.

Surface Treatments

DayTride® (XN) - A low temperature, cost- effective surface application that treats all exposed surfaces. Provides increased dimensional stability. Ideal for punches and die but- tons. Approx. hardness: RC65-73.

XVP - A thin film coating provides superior hardness (harder than carbide). Super-smooth finish on the point helps reduce galling and maintenance. Ideal for higher-than-normal punching frequency.

XPS - Super-smooth polish on the point to reduce galling and improve punch life. Use with the appropriate coating for your application to maximize punch life and reduce maintenance costs. Excellent for extruding applications.

Abrasive Wear

DayTiN® (XNT) - Excellent wear resistance and lubricity. Not recommended for stainless steel, copper, or nickel. A good general- purpose coating. Approx. hardness: *Vickers 2300.

TiCN (XCN) - Ultra-hard (harder than carbide), thin coating. Provides superior abrasive wear resistance and lubricity. A very good general- purpose coating for all materials. Upgrade over XNT. Approx. hardness: *Vickers 3000.

DayTAN™ (XAN) - Ultra-hard (harder than carbide), high-aluminum coating. Provides high temperature resistance. Well-suited for applications where surface heat is generated. Ideal for HSLA, dual phase, and TRIP steels. Upgrade over XCN. Approx. hardness: *Vickers 3400.

ZertonPlus™ (XNA) - Superior hardness (harder than carbide); provides superior abrasive wear resistance and excellent lubricity. Provides highest temperature resistance, thermal shock stability, & hot hardness. Approx. hardness: *Vickers 3200.

Adhesive Wear

XNM - A solid lubricant coating. Provides both lubricity and wear resistance not available from other PVD or CVD processes. Ideal for aluminum, copper, pre-painted, and galvanized steels. Approx. hardness: *Vickers 2000.

XCD - Diamond-like carbon coating. Combines high hardness with an extremely low coefficient of friction. Good protection against abrasive and adhesive wear. Ideal for aluminum. Approx. hardness: *Vickers 5000.

XCDH - Super-smooth finish combined with advanced DLC coating for a very low coefficient of friction with extremely high wear resistance. Approx. hardness: *Vickers 5000.

XCDP - Super-smooth finish combined with a DLC coating for a very low coefficient of friction with high wear resistance. Excellent for stamping aluminum. Approx. Hardness: Vickers 2800.

Extrusion Coatings

XNP - The ultimate coating for improved resistance to galling; excellent wear resistance, superior surface finish, and high lubricity. Ideal for extruding and forming applications. Tolerance is ±.0002”. Approx. hardness: *Vickers 3100.

XNAProgress (XNAP) - Ultra-hard coating that absorbs shear stress; provides excellent high-temperature resistance. Ideal for stamping where tools are exposed to extreme stress pro- files. A good alternative to TD coating without the dimensional changes associated with that process. Approx. hardness: *Vickers 3200.

Miscellaneous Coating

CRN - Excellent adhesion, high toughness, and good corrosion resistance. Primary applications are metal forming (copper, brass, & bronze), metal die casting, and plastic injection molding. Approx. hardness: *Vickers 1800-2100.

Classified Shapes

Clearance

DAYTON will assure the proper clearance of matrixes to the punch when ordered in this manner.

Standard Ball Seat Locations

Standard Ball Seat Locations

The Standard Ball Seat Location is at 90°. Alternate locations of 0°, 180° or 270° can be specified at no additional cost.

Custom Ball Seat Locations

Custom Ball Seat Locations can be specified as BS and degrees counter-clockwise from 0°.

Views

Views are: reflected view of punch and plan view of matrix.

Corner Dimensions (1) (2)

Dimensions should be to the theoretical sharp corners for C22, C24, C25, C34, C61 and C88. Some reduction of these dimensions will result from fitting the punch and matrix under conditions where clearance is .0015 or less per side.

Fillets matched with sharp corners reduce the clearance per side (i). If the clearance is .0015i or less, DAYTON will break sharp corners when the punches and matrixes are ordered together. This reduces assembly time and the risk of the edge breaking during operation.

Check your P&W dimensions to be certain the diagonal G does not exceed the maximum shown.

C10 (H)

C11 (K)

C12 (N)

C13

C14

C15

C16

C17

C18

C19

C20

C21

C22

C23

C24

C25

C26

C27

C28 (J)

C29

C30

C31

C32

C33 (V)

C34

C35

C36

C37

C38

C39

C40

C41

C42

C43

C44

C45

C46

C47

C48

C49

C50

C51

C52 (Y)

C53

C54

C55

C56

C57

C58

C59

C60

C61

C62

C64

C65

C66

C67

C68

C69

C70

C71

C72

C73

C74

C75

C76

C77

C78

C79

C80

C81

C82

C83

C84

C85 (Z)

C86

C87

C88

C89

C90

C91

C92

C93

O

R

| Component Brand | TuffPunch |

|---|---|

| Measure | Metric |

| Component Type | Punches |

| Punch Shape | Classified Shapes |

Product Applications

frequency and heavier-than-normal impact punching activity occurs and where optimum performance is required.

Dayton Jektole® Punches; Regular Punches; and Punch Blanks.

Unique Head Design

All Dayton TuffPunch® products are designed with a 10° angled head with a diameter equal

to the shank diameter (see photo). This design allows the perforating forces to travel

up from the shank and completely through the head. This eliminates the lateral shock

waves that would otherwise put stress on the outer edge of the head, resulting

in frequent failures—especially in heavy-duty applications.

All Dayton TuffPunch® products are designed with a 10° angled head with a diameter equal

to the shank diameter (see photo). This design allows the perforating forces to travel

up from the shank and completely through the head. This eliminates the lateral shock

waves that would otherwise put stress on the outer edge of the head, resulting

in frequent failures—especially in heavy-duty applications.

In addition, Dayton TuffPunch® products are available in common shear angle configurations to reduce punch load and minimize the risk of slug pulling. Shear angle configurations include: nail point; chamfer; conical; double shear; and single shear. For more information, see “Alterations” tab.

Cryogenic Treatment Standard

DayKool™ (XCR)—a cryogenic steel conditioning process used primarily with hard, thick materials to improve strength, toughness, and dimensional stability—is standard on all Dayton TuffPunch® products.

dispersed carbides provide more evenly distributed wear); less sharpening time; no loss of resistance after sharpening; longer die runs; and less downtime.

Special Features

Punches, retainers, and punch blanks are available in sizes other than those listed in the configurator. These special order products can be manufactured for a slight additional charge.

When configuring, you are asked to specify different designations for various non-standard dimensions. Once you have set the base information you can choose from the list of available alterations. Below is for reference.

Length Alterations

XBR (Straight Before Radius) It is recommended that point lengths be kept as short as possible for optimum strength

| XL | Overall Length Shortened (1.00 min.)

Stock removal from point end which shortens L1 length |

| XLB | Overall Length Shortened

Stock removal from point end. Point length L1 maintained (Min. shank length .75) | |

| LL | Precision Overall Length

Same as XL except overall length is held to ±.001 | |

| XK | No Side Hole For air ejection. No cost | |

| XS | Shear Angles See information below | |

| XJ | Smaller Jektole Components |

Shear Angles (XS)

TuffPunch® products are available in common shear angle configurations for all standard shapes.

Shear angles are available in any angle. Specify angle in whole degrees. if half degree is necessary, specify as a decimal, e.g., 8.5° (tolerance on all angles is +-15 minutes.) Use the chart below to determine the product designation, then simply add the alteration code shown next to the drawings, along with the angle desired.

LL not available on XS19, XS21, XS22 and XS23.

Our TuffPunch®

line of punches are available with the most common locking devices, flat, double flat and dowel. The standard location is at 0°, alternate locations of 90°, 180°, or 270° are available at no additional charge.

If you require a custom location we offer that as well use the Custom Locations codes below and specify your angle. All custom locations are measured counterclockwise from 0°.

Single Flats

For Standard and Alternate Locations, specify X2

For Custom Locations, specify X5

Double Flats

For Standard and Alternate Locations, specify X3

For Custom Locations, specify X6

Second Flat is Always Parallel to the first flat.

Additional Flats

Standard and Alternate Locations

| Code | Depth | Length |

| X81 | .060in (1.5mm) | .500in (13mm) |

| X82 | .060in (1.5mm) | .625in (16mm) |

| X83 | .060in (1.5mm) | .750in (20mm) |

| X84 | .060in (1.5mm) | Full Length |

| X85 | .093in (2.5mm) | .500in (13mm) |

| X86 | .093in (2.5mm) | .625in (16mm) |

| X87 | .093in (2.5mm) | .750in (20mm) |

| X88 | .093in (2.5mm) | Full Length |

| X89 | Specify Dimension | |

Custom Locations

| Code | Depth | Length |

| X91 | .060in (1.5mm) | .500in (13mm) |

| X92 | .060in (1.5mm) | .625in (16mm) |

| X93 | .060in (1.5mm) | .750in (20mm) |

| X94 | .060in (1.5mm) | Full Length |

| X95 | .093in (2.5mm) | .500in (13mm) |

| X96 | .093in (2.5mm) | .625in (16mm) |

| X97 | .093in (2.5mm) | .750in (20mm) |

| X98 | .093in (2.5mm) | Full Length |

| X99 | Specify Dimension | |

Dowel Slots

For standard and Alternate Locations,

specify X4 (.125 Dowel)

or X41 (.1875 Dowel)

For Custom Locations specify X7 (.125 Dowel) or X71 (.1875 Dowel)

Location Tolerance

Coatings & Treatments

Punches can be coated to increase material hardness, reduce galling, and improve wear/ and or corrosion resistance.

Surface Treatments

DayTride® (XN) - A low temperature, cost- effective surface application that treats all exposed surfaces. Provides increased dimensional stability. Ideal for punches and die but- tons. Approx. hardness: RC65-73.

XVP - A thin film coating provides superior hardness (harder than carbide). Super-smooth finish on the point helps reduce galling and maintenance. Ideal for higher-than-normal punching frequency.

XPS - Super-smooth polish on the point to reduce galling and improve punch life. Use with the appropriate coating for your application to maximize punch life and reduce maintenance costs. Excellent for extruding applications.

Abrasive Wear

DayTiN® (XNT) - Excellent wear resistance and lubricity. Not recommended for stainless steel, copper, or nickel. A good general- purpose coating. Approx. hardness: *Vickers 2300.

TiCN (XCN) - Ultra-hard (harder than carbide), thin coating. Provides superior abrasive wear resistance and lubricity. A very good general- purpose coating for all materials. Upgrade over XNT. Approx. hardness: *Vickers 3000.

DayTAN™ (XAN) - Ultra-hard (harder than carbide), high-aluminum coating. Provides high temperature resistance. Well-suited for applications where surface heat is generated. Ideal for HSLA, dual phase, and TRIP steels. Upgrade over XCN. Approx. hardness: *Vickers 3400.

ZertonPlus™ (XNA) - Superior hardness (harder than carbide); provides superior abrasive wear resistance and excellent lubricity. Provides highest temperature resistance, thermal shock stability, & hot hardness. Approx. hardness: *Vickers 3200.

Adhesive Wear

XNM - A solid lubricant coating. Provides both lubricity and wear resistance not available from other PVD or CVD processes. Ideal for aluminum, copper, pre-painted, and galvanized steels. Approx. hardness: *Vickers 2000.

XCD - Diamond-like carbon coating. Combines high hardness with an extremely low coefficient of friction. Good protection against abrasive and adhesive wear. Ideal for aluminum. Approx. hardness: *Vickers 5000.

XCDH - Super-smooth finish combined with advanced DLC coating for a very low coefficient of friction with extremely high wear resistance. Approx. hardness: *Vickers 5000.

XCDP - Super-smooth finish combined with a DLC coating for a very low coefficient of friction with high wear resistance. Excellent for stamping aluminum. Approx. Hardness: Vickers 2800.

Extrusion Coatings

XNP - The ultimate coating for improved resistance to galling; excellent wear resistance, superior surface finish, and high lubricity. Ideal for extruding and forming applications. Tolerance is ±.0002”. Approx. hardness: *Vickers 3100.

XNAProgress (XNAP) - Ultra-hard coating that absorbs shear stress; provides excellent high-temperature resistance. Ideal for stamping where tools are exposed to extreme stress pro- files. A good alternative to TD coating without the dimensional changes associated with that process. Approx. hardness: *Vickers 3200.

Miscellaneous Coating

CRN - Excellent adhesion, high toughness, and good corrosion resistance. Primary applications are metal forming (copper, brass, & bronze), metal die casting, and plastic injection molding. Approx. hardness: *Vickers 1800-2100.

Classified Shapes

Clearance

DAYTON will assure the proper clearance of matrixes to the punch when ordered in this manner.

Standard Ball Seat Locations

Standard Ball Seat Locations

The Standard Ball Seat Location is at 90°. Alternate locations of 0°, 180° or 270° can be specified at no additional cost.

Custom Ball Seat Locations

Custom Ball Seat Locations can be specified as BS and degrees counter-clockwise from 0°.

Views

Views are: reflected view of punch and plan view of matrix.

Corner Dimensions (1) (2)

Dimensions should be to the theoretical sharp corners for C22, C24, C25, C34, C61 and C88. Some reduction of these dimensions will result from fitting the punch and matrix under conditions where clearance is .0015 or less per side.

Fillets matched with sharp corners reduce the clearance per side (i). If the clearance is .0015i or less, DAYTON will break sharp corners when the punches and matrixes are ordered together. This reduces assembly time and the risk of the edge breaking during operation.

Check your P&W dimensions to be certain the diagonal G does not exceed the maximum shown.

C10 (H)

C11 (K)

C12 (N)

C13

C14

C15

C16

C17

C18

C19

C20

C21

C22

C23

C24

C25

C26

C27

C28 (J)

C29

C30

C31

C32

C33 (V)

C34

C35

C36

C37

C38

C39

C40

C41

C42

C43

C44

C45

C46

C47

C48

C49

C50

C51

C52 (Y)

C53

C54

C55

C56

C57

C58

C59

C60

C61

C62

C64

C65

C66

C67

C68

C69

C70

C71

C72

C73

C74

C75

C76

C77

C78

C79

C80

C81

C82

C83

C84

C85 (Z)

C86

C87

C88

C89

C90

C91

C92

C93

O

R

- Component Brand:

- TuffPunch

- Measure:

- Metric

- Component Type:

- Punches

- Punch Shape:

- Classified Shapes

You might also be interested in the following products

Configure Product

- {{segmentOption.Description}}

-

{{segmentOption.Description}}

- {{segmentOption.Description}}

| {{summaryItem.Description}}: | None |

|---|---|

We’re the industry-leader in the production of manufacturing tools such as special punches, die components, die details, punch blanks and metal-stamping tools.

Get In Touch