High Strength Steels

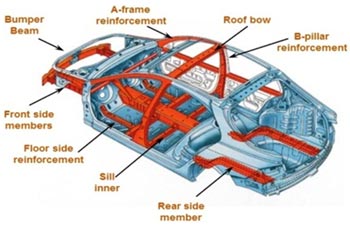

A Key Material in Critical Safety Components

Auto manufacturers are challenged by increasing oil prices, stricter emission standards, and greater demands on safety. Lighter and stronger steels in structural components are now required from OEMs and suppliers. How does a die designer handle forming and piercing with these new High Strength Steels (HSS)?

Typical High Strength Steel Components in Automotive Bodies

(Courtesy: VW-EU)

Types of high strength steels

HSS grades are varied. Some grades have elongation similar to that of conventional cold or hot rolled steels with higher yield and tensile strengths such as High Strength Low Alloy (HSLA) 420. Other grades have very little elongation and exhibit very high yield tensile strengths. Some grades achieve high tensile strengths through a hardening process. These materials behave differently enough to warrant special treatment in the die design and presswork.

Dent resistant grades

One of the earlier forms of high strength steel used for automotive components came in the form of Dent Resistance (DR) grades. These DR grades were desirable in auto components that required increased load carrying capability and improved crash energy management. But their most important factor for mass reduction was a reduction in sheet metal thickness. However, it is well known that an increase in strength typically comes with a loss in ductility or formability. Steel manufacturers made these grades available in two flavors — a Bake Hardenable (BH) grade and a Non-Bake Hardenable (NBH) grade.

The difference between BH and NBH

BH grades achieve an increase in strength through the process of post draw baking cycle. This is typically done in a paint dry oven after forming. NBH grades gain their increase during the forming operation through work hardening. Die design should account for larger forming forces on tools used in NBH forming, and should favor a relatively more generous drawing geometry (corner radii). You could expect higher contact pressures during forming with NBH grades. Severe galling is a possibility and coatings may be recommended on certain applications.

High Strength Low Alloy (HSLA) Steels

Let's discuss one of the versatile HSS grades being used in the industry today - High Strength Low Alloy (HSLA) grades.

Typical microstructure of HSLA sheet material - similar to other low carbon steel grades microstructure, shows very little alloying content

(Courtesy: Arcelormittal)

Strength and directionality

HSLA grades are low carbon sheet grades with alloying elements added to improve mechanical strength. Yield strengths typically range from 45 to 120 Ksi (300 to 830 MPa). The degree of mechanical strength imparted into the material is determined through meticulous process control during rolling of these sheets. This may be controlled by reductions in cross-section, the number of passes and rolling temperature. Unlike DR grades, this results in HSLA grades that exhibit high yield and tensile strength in as received condition. Apart from influencing strength of the sheet, the rolling process also induces a lot of directionality which lowers their formability and improves bendability. Therefore, most of HSLA components manufactured today are bent, flanged or roll-formed with very minimal forming.

Limiting springback

One major issue that manufacturers will experience when processing HSS grades will be controlling or minimizing springback. With high yield strength and directionality in these grades, the possibility for spring back is significantly higher. Die designers should pay close attention to part geometries that are more likely to produce high residual stresses after forming and result in part distortion and springback. Although springback prediction using CAE programs is becoming more accurate, die designers could eliminate a lot of springback related issues by incorporating minor changes in part geometry or in forming process. Considerations include:

- accounting for over bending

- eliminating bending around small radii or forming of sharp corners in one step

- ensuring that part undergoes some stretching around critical bending surfaces

- using strengthening elements.

Additionally, care should be taken to ensure that the tooling material selected for forming operations can withstand the high contact pressures experienced during forming these grades. Coatings may be recommended if the sheet material is galvanized or if galling tends to be an issue in maintenance.

Dual Phase Grade

Dual Phase (DP) grades are quickly gaining popularity. DP grades allow automakers to down-gage further than they could with HSLA grades. But this movement has come with an unforeseen cost – the challenge to successfully produce parts with DP grades. While forming of HSLA grades has been nothing more than a step up from forming low carbon steel grades in terms of mechanical strength, forming DP grades have proved to be a whole other animal, resulting in longer prototyping phases, multiple iterations in tool design, and a lot of unexpected press shop maintenance issues.

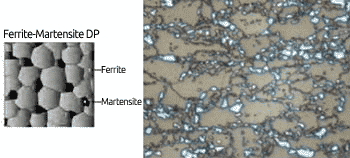

Typical microstructure of DP sheet material - darker regions show martensitic phase trapped in lighter regions shows ferritic phase in matrix.

(Courtesy: World Auto Steel/Arcelormittal)

Balancing the phases

These challenges originate in Dual Phase's composition. Unlike HSLA grades that were essentially low carbon sheets with alloying elements added to increase strength, DP is essentially a material with two different phases as its name indicates – one ferrite and the other martensite. The ferrite phase being softer and of lower strength provides good ductility. DP has lower yield strengths when compared with equivalent HSLA grades, but the presence of the martensite phase that is harder and of higher strength changes the yielding behavior of the material drastically. Additionally, steelmakers vary the amount of the martensite phase to achieve higher mechanical properties. A low strength DP grade might behave quite differently in presswork compared to a high strength DP grade, requiring tool makers and die designers to carefully design and evaluate forming techniques for components from each DP grade.

Dual phase springback

With DP grades being used in automotive crash test structures such as side impact cross-bars and pillar members - all of which possess a channel type cross-section, and in tandem with the fact that use of these grades facilitates use of thinner sheet materials that are less capable of retaining part shape, results in possibly the greatest challenge in forming these grades – controlling springback. This is compounded by the fact that there is very little or no experience base in the industry for springback compensation with DP grades. Several studies have been conducted by automotive OEMs and tooling vendors to identify solutions to minimize springback and we will discuss this next.

Solutions to Springback

In continuation of the discussion on challenges in forming DP grades, eliminating springback requires forensic analysis to eliminate or minimize the root of the issue (i.e. residual elastic stresses in the final part). Although it would be evident that higher strength steel grades with higher work hardening would have relatively larger potential for springback than their conventional steel counterparts, the solutions to minimize springback are not as evident.

Two "U" channel members formed in the same die - Channel on the left formed with DP 350/600 and channel on the right formed with HSLA 350/450

(Courtesy: World Auto Steel)

Preventing problems in die design

With steelmakers controlling mechanical properties by varying compositions of the two phases in DP grades, it would appear that experiences learned from forming a low strength DP grade like DP 350 would not be as applicable with a higher strength DP grade like DP980. However, some elementary techniques addressed early on in the die design phase such as stretching the part during forming to ensure that resultant stresses in the part are primarily tensile, eliminating small forming radii from the tools, and over bending would greatly help alleviate a lot of production issues. For example, studies on DP600 have shown that the minimum forming radius needs to be at least three times the material thickness, and DP600 needs to be over bent by at least 6°.

Selecting the right tools

Tooling selection should be made bearing in mind that these grades generate a lot of contact pressure. Consequently, draw dies, draw beads, trim tools, and punches would most likely require a material upgrade. A coating composition with high surface hardness and lubricity would also help reduce the amount of sliding wear on tools and prolong life. Piercing tools will experience significantly higher stripping forces with DP grades, and the use of a strong stripping unit would be highly recommended. Additionally, care should be taken to ensure that the piercing tool makes contact with the part in a perpendicular fashion. Any deviation would result in uneven loading and lead to premature failure of the tool. In instances where this is unavoidable, shear angles should be considered. Studies have shown that while piercing DP800 grade sheets, shear angles could potentially lower the punch load by as much as 25%.

Avoiding cracking

The second major production hurdle with DP grades is the higher potential for edge cracking in pierced holes or along trimmed edges. With majority of the DP components being used for crash safety, cracking or micro-cracking along the periphery of holes or trimmed surfaces reduces the overall fatigue strength of the component. This leads to a premature failure and should be avoided at all costs.

Eliminating Edge Cracking

Shearing operations like slitting, blanking, piercing and trimming reduce the stretch-ability of the material locally around the cut edge. This is a characteristic that should receive special attention especially when processing sheet materials like DP grades. Why? Most structural components made from DP grades are typically used as crash or load absorbing members in automobiles. In the event of a crash, minor imperfections in the quality of the cut edge act as origins for cracks or help in propagating cracks, compromising the integrity of the component.

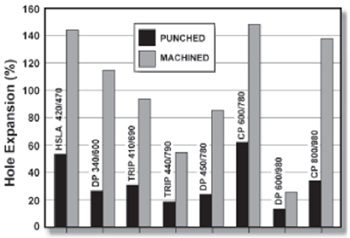

Hole expansion test data for typical HSS grades

(Courtesy: World Auto Steel)

The Hole-Expansion Test

Among all the factors that influence the possibility of cracks occurring along a cut edge, the sensitivity of the sheet material is one that manufacturing has no control over. However, by understanding how sensitive the material is to cracking, die designers and tool makers can account for it early on in the development process. Consequently, several sheet suppliers provide test data that reflect the sensitivity of the material to edge cracking. The most common test is the hole-expansion test. This test measures the % expansion of a pierced hole using a conical or flat bottom punch prior to cracking. The higher the % the less sensitive the material is, i.e. with lower %, the piercing process will need to be controlled tighter as the material is highly sensitive. The chart shows the typical expansion ratios for some popular HSS grades, and it can be observed that HSLA grades have higher % ratios as compared to DP grades, indicating HSLA grades are less sensitive. In turn, tooling experience from HSLA grades would not necessarily work when processing DP grades.

Reducing Cracking

Under production conditions, improving the quality of the sheet cut edge will reduce the potential for cracking. One simple method to improve sheet cut edge quality would be to monitor the quality of the tool’s cutting edge – a worn tool will produce poor quality cut edge with more imperfections and a higher chance for failure. Additionally, use of tool steel material that can retain the sharpness of the tool cutting edge longer, and can withstand longer intervals between re-sharpenings would be preferred, such as PM M4 grades. The use of a coating will help improve lubricity at the cutting edge, and minimize tool wear, and should be considered whenever clearances are tighter than recommended. Clearance selection will also dictate the sheet cut edge quality, while a tighter clearance will produce a better sheet cut edge, it will reduce the tool life significantly. In turn, a balance must be achieved between tool life and an acceptable sheet cut edge quality. Typically, clearances would increase with increasing strength of the sheet, i.e. DP980 grades needing more clearance while shearing than DP590 grades, but it should be noted that with increasing thickness the load of the cutting edge of the tools are also increasing, in turn clearance should be increased with increasing material thickness also, i.e. 2.5mm thick DP590 should have larger clearance while shearing than 1.2mm DP590.

TRIP & MART

Now let's discuss two remaining HSS grades, TRIP and MART. Unlike the other grades discussed previously, these two grades are not as popular in the US due to lack of availability.

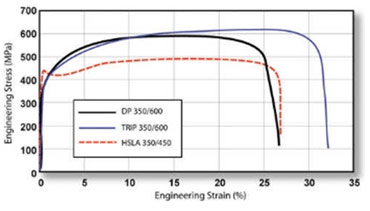

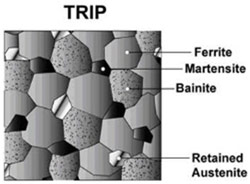

Transformation Induced Plasticity (TRIP)

TRIP steels, the more popular of the two grades, were developed to improve ductility while maintaining similar strength levels as the DP grades (see graph). The microstructure of these grades differs from the other grades in that it contains regions of austenite (softer phase) in a ferritic-bainitic matrix. During deformation (plastic strain), this austenitic phase transforms into martensite (harder phase), giving these grades an unique name – TRansformation Induced Plasticity (see microstructure).

Typical microstructure of TRIP grade steel and a comparison of yielding curves for DP, TRIP & HSLA (Courtesy: World Auto Steel)

TRIP grades also use additional alloying elements to delay fracture or cracking, thereby improving ductility. This makes them more expensive and cost prohibitive for most automotive components. But in cases wherein a low edge cracking grade is required, such as components found in the loading path of a vehicle body, TRIP steel find its uses.

As a general rule of thumb, any guidelines set forth for processing DP grades would be applicable for TRIP steels, as they are more ductile. But care should be taken while selecting tools, esp. for shearing or piercing, and bending or flanging type operations. With the ability to undergo longer elongations, TRIP steels tend to spring back more and tools might tend to get worn out quicker if appropriate clearances are not employed. Over bending to compensate for springback, and the use of a premium powder material tool steel such as PM-M4 would be highly recommended.

Martensitic (MART)

MART grades have the highest strength compared to all the other HSS grades available today. Some MART have tensile strengths as high as 1500MPa or 217Ksi. This is because, unlike other HSS grades, MART grades are composed purely of a low carbon martensitic microstructure. They gain their strength from the percentage of martensitic phase in the microstructure, and this percentage is usually very high. Steelmakers control this martensitic phase percentage, and in turn finishing strength by controlling the percentage of carbon added to the composition. Being nearly completely martensitic, these grades exhibit limited ductility, and perform poorly under drawing, forming or coining conditions. Consequently, they are not popular among stampers, and are typically found in simple auto components. There are however, studies being conducted to develop hot forming processes that can successfully stamp and form complex shapes at high temperature and cool the parts in the die to retain some of the high strength characteristics. But the high production viability of these hot stamping processes is yet to be proven.