Dayton Slug Control System

Guaranteed Solution To Slug Pulling

Dayton Slug Control

is a method of reducing the risk of slugs being pulled to the die surface during withdrawal of the punch. The slugs are trapped in the land of the die buttons until they fall freely through the relief. It has no effect on hole size and will not

require any changes in your regrind practices. Dayton Slug Control is effective throughout the life of the die buttons.

Dayton Slug Control

is a method of reducing the risk of slugs being pulled to the die surface during withdrawal of the punch. The slugs are trapped in the land of the die buttons until they fall freely through the relief. It has no effect on hole size and will not

require any changes in your regrind practices. Dayton Slug Control is effective throughout the life of the die buttons.

Customized To Your Application

Slug Control is based on your application, insuring that you are getting a customized remedy to solve your slug pulling problem. Each die button is produced based on information you supply. It requires no redesigning of your tooling, no special drawings, and it is on a Firm Delivery Schedule. On standard die buttons add three days to the normal delivery. For example round Versatile die buttons with the Slug Control alteration will ship in four days. This alteration is not limited to Versatile products. It works in any die button whether it has a counterbored hole or a tapered hole in the slug relief area. It works in shapes as well as round holes.

Slug Control is designed around a series of interference points on the slug that are produced during penetration into the die button. An exact amount of “trap” is applied to the slug to prevent it from returning to the die surface. This innovative process uses a series of grooves inside the die button. The slug expands into the grooves, effectively trapping it. This method of controlling slugs is so dependable, it’s guaranteed!

Test this Slug Control system in your die and we will offer you this unconditional guarantee: Use Dayton Slug Control in a stamping die now pulling slugs. If for any reason you are not completely satisfied, we will refund the full cost of the Slug Control alteration. (We cannot guarantee the retention of slugs when clearance exceeds 10% per side.)

Using the Dayton Slug Control system reduces or eliminates the following:

- Diemaker treatments such as:

- breaking all cut edges

- bellmouthing die buttons

- dome or shear angles on punch points

- dulling punches

- notching punches

- entering punches deeper

- Punch breakage due to double hits

- Costly vacuum sleeves

- Die maintenance time

- Press downtime, wasted material and lost man hours

The advantage of Dayton’s Slug Control system over other methods is that it is guaranteed.

Dayton's slug control method is available on all die buttons: tapered and counterbored.

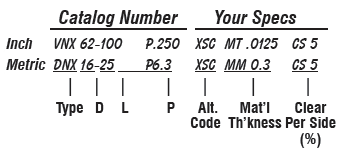

Dayton Slug Control is Easy to Order

Dayton Slug Control is as easy as specifying a catalog number. Add the information that is unique to your application to the die button catalog number. See the example below:

You must specify XSC for alteration, material thickness and clearance per side as a percent.

This information will be entered into our computer to generate a program to alter the land of the die button and end your slug pulling problems forever!