Surface Treatments and Coatings for Improved Productivity

Dayton's leading-edge coatings and other unique surface treatments have been developed to improve inplant performance by increasing tool hardness and wear resistance.

Surface Treatments

DayKool™ (XCR)

A cryogenic steel conditioning process used in addition to heat treating. An effective way to achieve optimum toughness, improved strength, and dimensional stability. Used primarily with hard, thick materials.

DayTride® (XN)

A low temperature, cost-effective surface application that treats all exposed surfaces. Provides increased dimensional stability. Ideal for punches and die buttons.

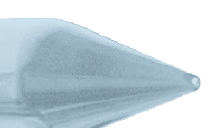

XVP

A thin film coating provides superior hardness (harder than carbide). Super-smooth finish on the point helps reduce galling and maintenance. Ideal for higher-than-normal punching frequency.

XPS

Super-smooth polish on the point to reduce galling and improve punch life. Use with the appropriate coating for your application to maximize punch life and reduce maintenance costs. Excellent for extruding applications.

Abrasive Wear

DayTiN® (XNT)

Excellent wear resistance and lubricity. Not recommended for stainless steel, copper, or nickel. A good general-purpose coating. Approx. hardness: *Vickers 2300.

TiCN (XCN)

Ultra-hard (harder than carbide), thin coating. Provides superior abrasive wear resistance and lubricity. A very good general-purpose coating for all materials. Upgrade over XNT. Approx. hardness: *Vickers 3000.

DayTAN™ (XAN)

Ultra-hard (harder than carbide), high-aluminum coating. Provides high temperature resistance. Well-suited for applications where surface heat is generated. Ideal for HSLA, dual phase, and TRIP steels. Upgrade over XCN. Approx. hardness: *Vickers 3400.

ZertonPlus™ (XNA)

Superior hardness (harder than carbide); provides superior abrasive wear resistance and excellent lubricity. Provides highest temperature resistance, thermal shock stability, & hot hardness. Approx. hardness: *Vickers 3200.

Adhesive Wear

XNM

A solid lubricant coating. Provides both lubricity and wear resistance not available from other PVD or CVD processes. Ideal for aluminum, copper, pre-painted, and galvanized steels. Approx. hardness: *Vickers 2000.

XCD

Diamond-like carbon coating. Combines high hardness with an extremely low coefficient of friction. Good protection against abrasive and adhesive wear. Ideal for aluminum. Approx. hardness: *Vickers 5000.

XCDH

Super-smooth finnish combined with advanced DLC coating for a very low coeficient of friction with extremely high wear resistance. Approx. hardness: *Vickers 5000.

XCDP

Super-smooth finish combined with a DLC coating for a very low coefficient of friction with high wear resistance. Excellent for stamping aluminum. Approx. Hardness: Vickers 2800.

Extrusion Coatings

XNP

The ultimate coating for improved resistance to galling; excellent wear resistance, superior surface finish, and high lubricity. Ideal for extruding and forming applications. Tolerance is ±.0002". Approx. hardness: *Vickers 3100.

XNAProgress (XNAP)

Ultra-hard coating that absorbs shear stress; provides excellent high-temperature resistance. Ideal for stamping where tools are exposed to extreme stress profiles. A good alternative to TD coating without the dimensional changes associated with that process. Approx hardness: *Vickers 3200.

Miscellaneous Coating

CRN

Excellent adhesion, high toughness, and good corrosion resistance. Primary applications are metal forming (copper, brass, & bronze), metal die casting, and plastic injection molding. Approx. hardness: *Vickers 1800-2100.

All coatings are PVD.

XAN, XNA, & XNAP are not recommended for Aluminum.

M2, PS, and PS4 tool steels can be coated without lowering the hardness (Rockwell). Coatings are not applied to A2 & D2 tool steels as these materials are subject to a softer hardness (Rockwell), hardness variations, size control problems, and bad adhesion.

* Vickers used when RC exceeds 80.

® DayTride and DayTiN are registered trademarks of Dayton Lamina.

™ DayTAN, DayKool, and ZertonPlus are trademarks of Dayton Lamina.

Select the Coating that Matches Your Specific Needs

Regardless of the end product(s) your company manufactures, you can improve the length of run time, reduce changeover time, improve uptime, and get more for your stamping dollar by selecting the type of coating that matches your individual operational capabilities.

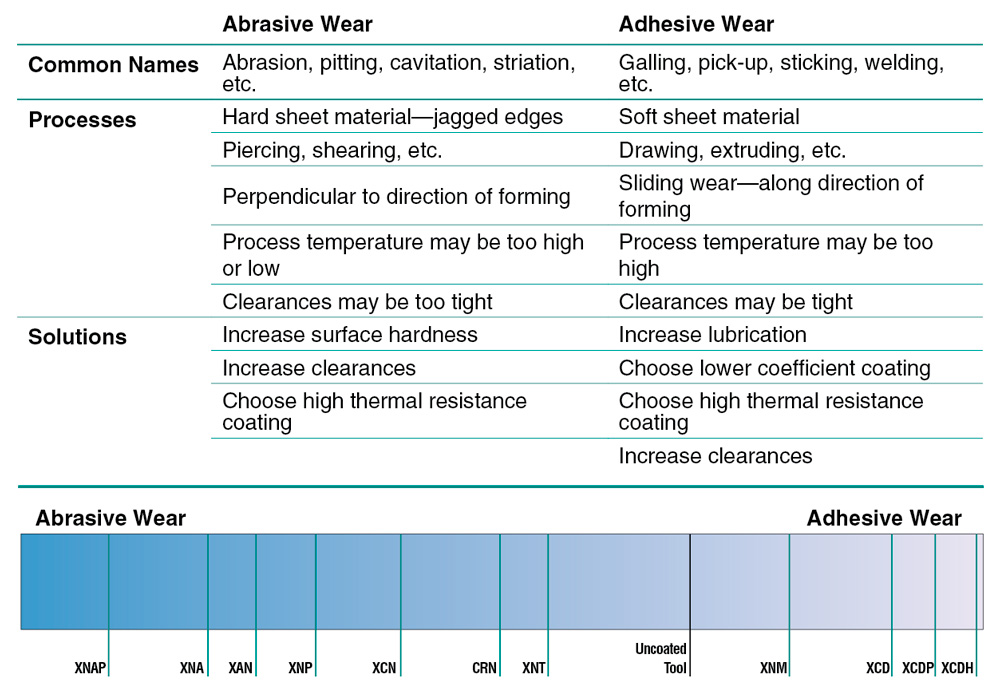

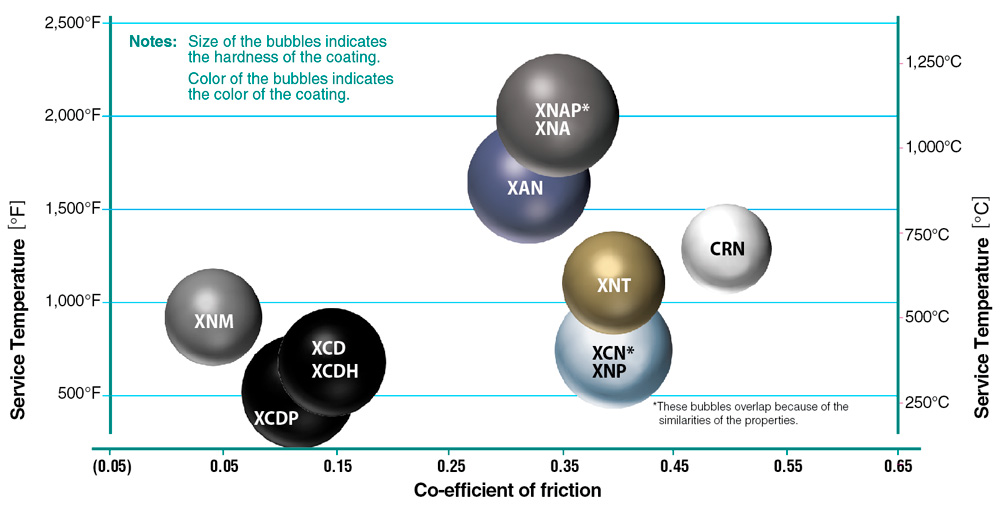

The chart describes the causes, effects, and solutions for abrasive wear and adhesive wear. The slider graph following shows the relative suitability for each type of treatment/coating in both of those categories. The bubble chart shows the relationship between service temperature, coefficient of friction, and hardness of the coating.

High Strength Steels (HSS)

Dayton coated punches are heat treated, precision ground, and made with high performance steel, including, but not limited to, the following:

- M2 - triple tempered HSS for longer runs. Performs well at higher temperatures; ideal for high-speed applications.

- PS - triple tempered with high vanadium and carbon particles. Higher wear and impact performance.

- PS4 -with 4% vanadium it provides higher wear resistance and improved toughness.

Dayton Delivers Full In-house Services and World-class Technical Support

Proprietary Coatings

Dayton is the industry's leader with the largest selection of state-of-the-art coatings–many of them tested in our lab.

In general, surface treatments enhance wear resistance and reduce surface friction above and beyond the capabilities of the substrate material (tool steel). However, surface treatments can be applied to a wide variety of tools steels with varying results.

Dayton's expertise in developing coatings to meet a specific requirement is second to none. We are constantly updating and improving these coatings to meet the ever-changing needs of our customers.

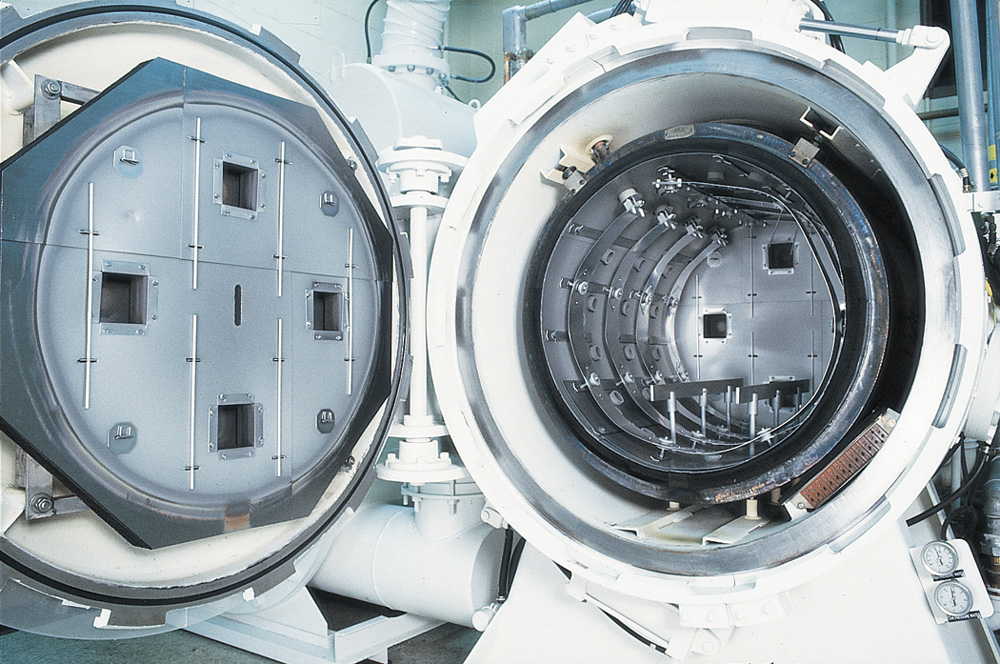

Heat Treatment

Punch performance depends on the design of the punch, the tool steel used, the finishing process, and other factors. Equally as important, the total performance is directly related to the quality of the heat treatment, i.e., hardening, cryogenics, or tempering.

In order to acquire optimum results for a given application, specific heat treatment guidelines must be followed. Careful monitoring of this process is essential to ensure the toughness of the tool steel-a prerequisite for high-quality stamping tools.

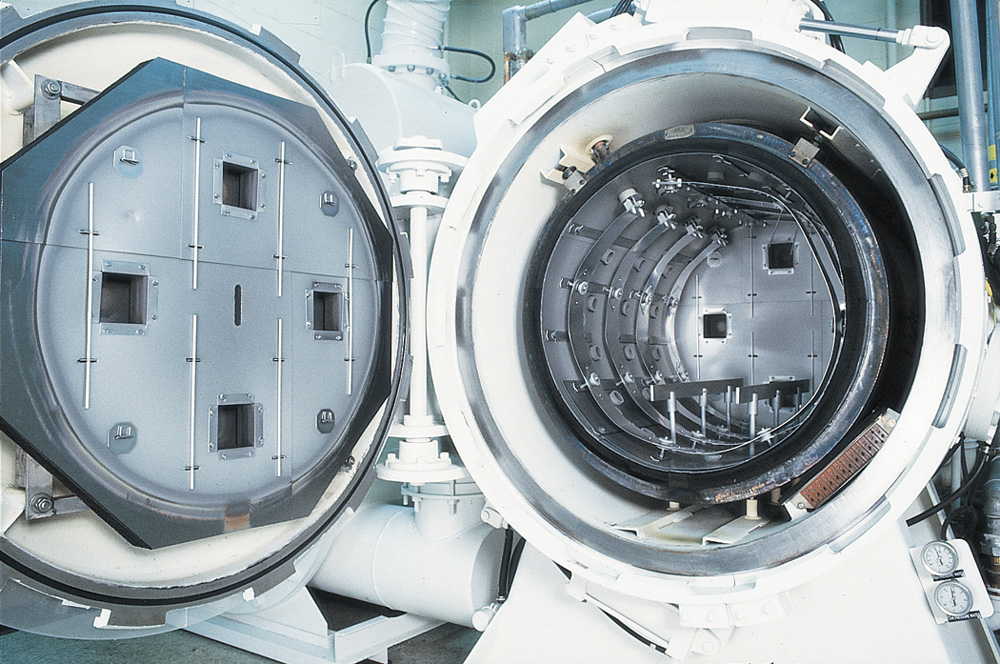

No company pays more attention to heat treating than Dayton Progress. Our in-plant facilities are constantly updated; product performance is regularly monitored; and our Chief Metallurgist oversees all heat treating processes.

Metallurgy Lab

Dayton's in-house metallurgy lab is designed to develop new products and to test and analyze the quality and viability of materials used in the manufacture of Dayton products. Our metallurgy lab comes fully equipped with top-quality testing and analytical equipment, and boasts best-in-class metallurgy and quality assurance.

Laboratory services include: hardness testing; metallography (e.g., coating thickness); and failure analysis. Routine testing (metallurgical, mechanical, and chemical) is performed on raw materials, semi-processed, and finished parts to determine compliance with quality requirements and design/manufacturing specifications.

Professional Technical Assistance

Dayton technical experts deliver a wide range of technical assistance and support-on the web, over the phone, or in person.

Services include component design assistance; manufacturing advice (e.g., precision finishing, such as polishing and lapping); heat treatment protocols (e.g., high-volume coating production); product applications and usage; and metallurgical expertise.

Designed with your needs in mind

Special Surface Treatments & Coatings

Dayton's leading-edge coatings and other unique surface treatments have been developed to improve in-plant performance by increasing tool hardness and wear resistance, thus reducing punching friction and torque, inhibiting galling and chip welding, and/or improving lubrication.

The standard surface treatments and coatings shown in this brochure were developed with a specific hardness rating based on the optimum usage of the punch. The hardness and type of coating you need depends on the steel selection, the application, the duration of the die run, and other factors.

In addition to our standard treatments and coatings, Dayton provides custom coatings/treatments based on your special needs and applications. For example, some steels can be coated to increase wear. Others can be coated for toughness, plus a single-layer coating can be applied that provides greater wear than a multi-layer coating.

For help in selecting the right surface treatment or coating for your operation, contact your nearest Dayton representative today.

VersaPlus®

Dayton VersaPlus® punches feature a thin film coating for superior, harder-than-carbide hardness; a super-smooth finish on the point, resulting in less galling and reduced maintenance; and more. Select Dayton VersaPlus® for optimum punch performance.